The light source of large-area solar simulator adopts short arc xenon lamp with spectrum similar to sunlight as the light source, which is composed of 6 short arc xenon lamps. Each xenon lamp adopts special optical design to ensure the uniformity of light spot.

Each xenon lamp is equipped with a light box, which is made of aluminum alloy to reduce weight. The light box is equipped with xenon lamp focusing mechanism, projection direction adjustment device, heat dissipation fan, electronic trigger, wiring terminal, high temperature and explosion-proof glass and other components, which can ensure the reliable operation of xenon lamp and conveniently adjust the spot size and irradiation direction.

The working distance is 4m-5m, the spot diameter is 1mx1m, the lamp array is adjusted by gearbox pitch, the adjustment angle is ± 30 °, astigmatism (non parallel light), the light intensity is a solar constant, the spot uniformity is 20% - 30%, and the illumination stability is 10%.

Spectral range: 0.2-2.5 μ m

Color temperature of light source: 6000K

Bulb luminous flux: 14500lm

Bulb luminous intensity: 1450cd

Bulb brightness: 40000 CD / cm ²

Bulb life: 2000h

Bulb life: 2000h

Bulb model: customized

Lamp arc size: 0.9 × two point five

Color rendering index: RA = 94

Optical elements: customized large reflective tile

Cooling mode: air cooling

Supply voltage: AC220V ± 10% / 50Hz

Lamp power: 500W

Output display: analog pointer indication

Output voltage: 17V

Current: 22-30a

Output current drift: ± 0.1% / h

Operating instructions for large area solar analog light source:

Introduction:

The xenon lamp array is a special equipment designed and developed according to the requirements of satellite solar cell panel illumination test, so as to replace the iodine tungsten lamp array previously used.

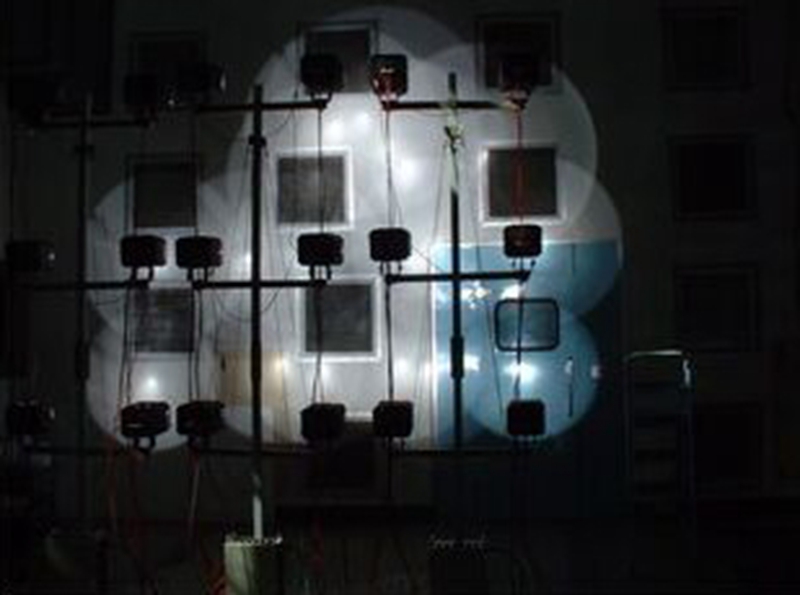

The lamp array uses short arc xenon lamps with spectrum similar to sunlight as the light source, which is composed of 18 750W short arc xenon lamps. Each 6 750W xenon lamps are installed on a movable support as a group, with a total of 3 groups. Three solar panels are illuminated respectively to ensure the irradiance requirements on the illuminated surface and achieve certain illumination uniformity. Each xenon lamp is equipped with a high reflectivity ellipsoidal reflector to effectively project the light radiation energy of the xenon lamp onto the illuminated surface.

Each xenon lamp is equipped with a light box, which is made of aluminum alloy to reduce weight. The lamp box is equipped with xenon lamp adjustment and sales mechanism, projection direction adjustment device, heat dissipation fan, electronic trigger, wiring terminal, high-temperature and explosion-proof glass and other components, which can ensure the reliable operation of xenon lamp, and conveniently adjust the spot size and irradiation direction.

Because the short arc xenon lamp can only work under the condition of DC power supply and requires a high stability of the power supply, each xenon lamp is equipped with a DC current stabilizing power supply, and 18 DC power supplies are divided into three groups, with 6 in each group. The power supply is a switching current stabilizing power supply to reduce the volume and weight of the power supply, improve efficiency and reduce the power consumption of the power source. Each slave source has an independent switch and output flow adjustment knob, which can control the on and off of each xenon lamp and the brightness of each xenon lamp.

The input of xenon lamp power supply is 220V AC, and three groups of DC power supplies are respectively connected between three phase lines and zero lines of three-phase AC power supply through air switch to ensure the balance of power grid.

The movable support is of light aluminum alloy structure, and casters are installed at the bottom. The support can be easily disassembled, assembled and transported.

Compared with the original iodine tungsten lamp array, this lamp array has the following advantages:

① Because the solar cell has a greater response to the spectrum of xenon lamp than that of tungsten lamp, the illumination effect of xenon lamp is better at the same power;

② Using the form of projection light, the illumination experiment can be carried out at a distance of 3 to 5 meters or more from the canvas, avoiding the possibility of accidental dumping of the lamp array and damage to the canvas;

③ The sharp temperature rise of the canvas caused by light is greatly reduced;

④ In general, the xenon lamp can be turned on after one discharge of the trigger. If the xenon lamp cannot be turned on after multiple discharges, the switch should be disconnected immediately to check whether the wiring is correct and whether there is a problem with the xenon lamp or trigger;

⑤ The brightness of xenon lamp has high brightness and strong ultraviolet light. The naked eye cannot look directly at it, and attention should be paid to the burn of human skin and eyes;

⑥ The time to adjust the xenon lamp to the maximum brightness shall be controlled within 10 minutes to avoid too high temperature in the lamp box;

⑦ When the lamp array works, ensure that the air inlet and outlet of the lamp box and the power supply are unobstructed without blocking. Poor ventilation can lead to xenon lamp explosion and power burning;

⑧ The explosion-proof glass shall be downward during the handling and transportation of the light box;